Ensuring the safety and wellbeing of workers is a top priority for any organisation, especially in industries such as manufacturing where occupational hazards are significant. Occupational health and safety protocols aim to prevent work-related injuries as well as protect workers. However traditional safety management approaches often fall short in effectively addressing evolving risks and optimising safety practices. That’s where MinRisk comes in. MinRisk, is a cutting-edge machine safety solution, offering a range of features and benefits that can revolutionise your on-site occupational health and safety practices related to machine safety. In this article we explore how MinRisk can optimise reporting, scale operations, provide mobile accessibility, integrate LOTO (Lockout/Tagout), replace cumbersome spreadsheets, and facilitate real-time safety action.

Streamlined Reporting

One of the key ways MinRisk promotes occupational health & safety is by providing streamlined reporting capabilities. Traditional reporting processes often involve manual data entry, making it time-consuming and prone to errors from double handling information. With MinRisk, reporting becomes efficient and hassle-free. The platform provides intuitive interfaces and automated workflows, enabling users competent users to update records. Real-time data entry and customisable reporting templates empower your team to generate comprehensive reports, track trends, and gain valuable insights for proactive safety measures. You and your team are then able to use this data to inform your safety plans going forward.

Optimising Health & Safety Across Large Businesses

MinRisk is designed to accommodate organisations of all sizes, offering scalability and optimisation features. Whether you operate a small manufacturing facility or a large, multi site industrial complex, MinRisk can adapt to your needs. The platform allows for centralised safety management, enabling efficient collaboration between different departments, sites, and teams. It streamlines processes, eliminates duplication, and provides a centralised database for easy access to critical safety information. It’s this ability to centralise information, at scale, and make it accessible that has such a positive impact on your safety bottom line. Safety information, when stored away, or when disjointed between teams, sites, or business units has no value.

MinRisk adds value to the data you already need to collect, allowing you to meet your occupational health and safety requirements without the headaches.

Mobile-Friendly Access to Health and Safety Data

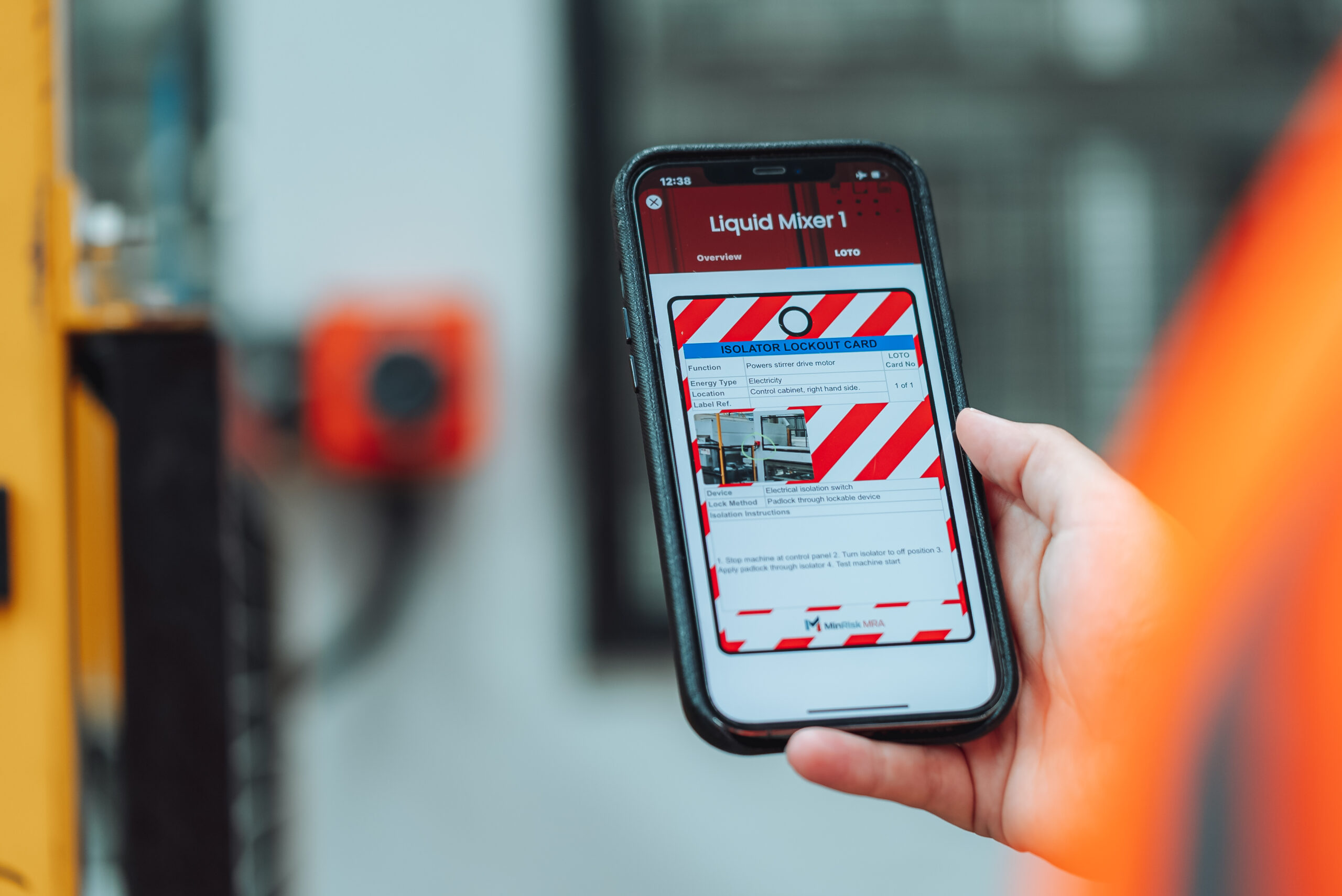

For your entire team to ‘buy in’ to your business wide occupational health and safety programme you need to reduce barriers to information and engagement. Needing separate hardware, restricting access to specific team members, or storage in an office with senior management, creates a barrier to use and engagement. That’s why we created MinRisk as a mobile application that can be signed into from a mobile device.

Your machine operator can log in from their mobile phone or tablet while standing in front of the machine or potential hazard, while at the same time and at a different site your safety officer can add information mark-up/make notes in real time, while your senior management can access much the same management information from their office PC, or from their smartphone on their way to their next meeting. Mobile friendly, real-time access to safety information transforms your onsite, team-wide and business-wide occupational health & safety protocols.

If more people have access to the information its more likely to be kept up to date and more likely to be acted upon.

LOTO Integration

Lockout/Tagout (LOTO) procedures are crucial for protecting workers from hazardous energy sources during equipment cleaning, maintenance or repair. They are an essential element of your occupational health and safety plan. MinRisk goes a step further by integrating LOTO processes within its Machine Risk Assessment process. This integration allows for a common platform for Machine Risk Assessment and LOTO, eliminating the need for separate systems. The streamlined approach ensures that LOTO procedures are effectively documented, controlled, monitored, and easily updated, minimising the risk of accidents caused by unexpected energy release.

Remove Excel from your Health and Safety Management System

MinRisk allows you to bid farewell to cumbersome spreadsheets and embrace the cloud. Excel sheets often become unwieldy, prone to errors, and lack real-time collaboration capabilities. By replacing the need for manual data entry and offering a centralised platform where safety information is stored, updated, and accessible MinRisk improves your health & safety outcomes. The intuitive interface simplifies data entry, retrieval, and analysis, enhancing accuracy, productivity, and compliance.

Moving your machine safety data from Excel to the cloud unlocks its full potential for health and safety outcomes. MinRisk enables risk concerns and safety goals to become an ongoing conversation within your team and across your organisation, improving your health and safety outcomes across the board.

Real-time action ensures daily Health and Safety Adherence

MinRisk empowers organisations to take effective action against machine safety risks. This proactive approach helps prevent accidents, minimises downtime, and fosters a safety-centric culture.

MinRisk machine safety software can significantly improve occupational health and safety at your manufacturing site. With MinRisk you can optimise reporting even at scale, utilise the cloud and replace Excel, take action with real-time access to assessments and reports. As well as keep your team safer with our LOTO capability and Hazard Overview cards in the Training App. By adopting MinRisk, you can streamline your safety management processes, enhance collaboration, mitigate risks, and ultimately create a safer working environment.

Want to learn more about how MinRisk can improve your onsite occupational health & safety?